Under periodic load, the surface of steel roller bearings is liable to be destroyed because of fatigue, i.e. chapped and flaked, which will greatly affect the service life of the steel roller bearing. Therefore, in order to prolong the working life of roller bearings, steel roller bearing materials must have high contact fatigue strength.

When the roller bearing is working, not only rolling friction but also sliding friction occurs between the ring, the roller, and the holder, which results in constant wear of the steel roller bearing components. In order to reduce wear and tear of steel roller bearings, maintain roller bearing accuracy and stability, and extend service life, bearing materials need to have good wear resistance.

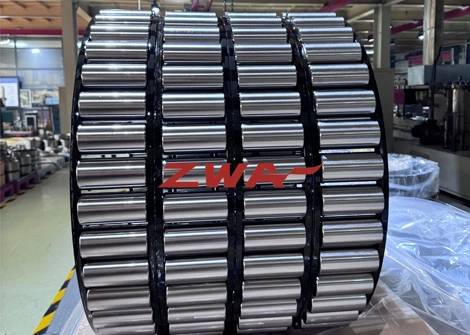

Hardness is one of the important indexes for evaluating steel roller bearing quality and has an indirect influence on its contact fatigue strength, wear-resistance, and elastic limit. In the practical appliance, the hardness of some roller bearing steel should be HRC61-65. High hardness endows roller bearings with higher contact fatigue strength and wears resistance.

In order to prevent the parts and finished products from being eroded and rusted in the process of processing, storage, and use, the bearing materials should have good rustproof properties.

During processing steel roller bearing components undergo a lot of cold and hot working processes. In order to meet the requirements of small quantity, high efficiency and high quality, roller bearing steel should have good processing performance, for example, cold and hot forming properties, cutting machining performance, hardenability, etc.