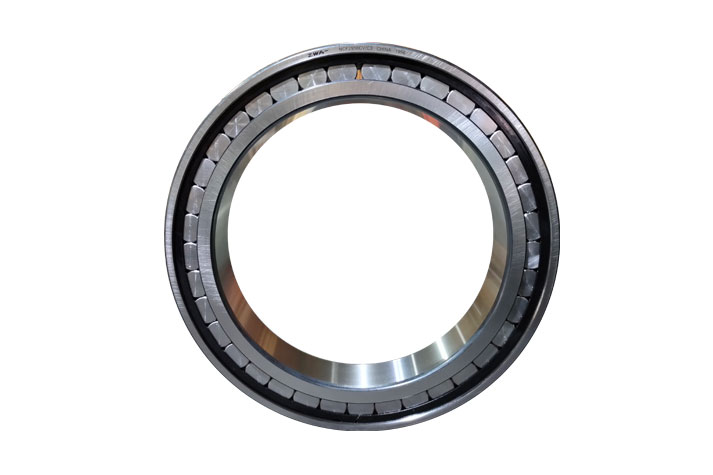

Single row cylindrical roller bearings with cages are part of radial roller bearings. Compared with the ball bearings’ balls, the rollers have a bigger contact to the roller axle. As a consequence, it can transfer higher forces, has higher stiffness, and in the same capacity load working condition, the diameter of the roller can be smaller. The rollers own profiled ends. For the basic design of all cylindrical roller bearings, the cylindrical rollers are guided within two ribs by at least one ring. This ring matches with the cage and rollers and become a fit unit. The other ring is removable and easier to mount and dismount.In general, the fit of the rings are tight one. Based on different arrangement of the ribs on the inner ring and outer ring, the bearings can be divided into NU, N, NJ, NF and NUP types. And the cage is usually pressed steel cage or machined brass cage.

Type NU and N allow the shaft to move in an axial direction within limits, applicable to use as a free end.

Type NJ and NF can bear a certain extent one-way axial loads. Type NUP can bear a certain extent two-way axial loads.

As one of the leading China cylindrical roller bearing manufacturers, ZWA has supplied thousands of pieces of single row cylindrical roller bearings to customers and those bearings favored the customer to reach the following goals:

Increase productivity

Decrease the cost

Higher operational security

Longer maintenance intervals

Longer bearing service life

Features of Single Row Cylindrical Roller Bearings are as follows

Bear not only high radial loads but also axial loads from one or two directions.

The separable design makes mounting, dismounting, maintenance, and inspection easier and more effective.

Higher fatigue limit

Lower heat generated from the bearings

Lower consumption on the lubrication

Application Fields of Single Row Cylindrical Roller Bearings are as follows

Steel, gearbox, crane, automobile, vibration equipment, and reducers, etc.