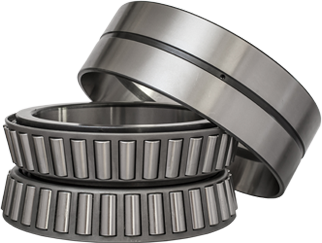

Tapered roller thrust bearings are composed of shaft washer, housing washer, cage and tapered rollers. The design of tapered roller thrust bearings is made to the extent that cones of shaft washer, housing washer raceways and roller surface are intersected at one point of bearing central line. Therefore, the rolling surface can form a kind of bearing whose limit rotating speed is much higher than cylindrical roller thrust bearings. Tapered roller thrust bearings are accommodated with higher axial loads and peak loads. Meanwhile, they are stiff and with little axial space. In general, tapered roller thrust bearings have three kinds of housing washers, one is housing raceway with a rib, the other is without a rib, and the last is with full complement rollers. In ZWA, we only catered the customers with the first 2 types. Cages for tapered roller thrust bearings in ZWA are steel or brass ones.

Based on different load capacity, ZWA’s tapered roller thrust bearings can be divided into two types, one is single direction tapered roller thrust bearings and the other is double direction tapered roller thrust bearings. Those bearings are mainly big-sized range. For single row tapered roller thrust bearings with big size, both shaft and housing washers have the raceways and one guide rib. For double direction tapered roller thrust bearings with big size, they are usually with a plane shaft washer or tapered raceways on both the shaft and housing washer. Because in general, the mounting of tapered thrust bearings of double direction is with a loose fit on the roll neck or in the chock, therefore, the shaft washer is equipped with one or two locating slots to stop the shaft washer rotating on its seats.

Feature of tapered roller thrust bearings

Bear heavy axial loads

Separable, easier for mounting, dismounting, inspection, and maintenance

Longer service life

Lower friction level

Application of tapered roller thrust bearings

Oil and gas industry, rolling mills, the hook of crane, gearbox, etc