Steel or other metal mills can be regarded as one of the few industries whose operating conditions are harsh. The high temperature and rotating speed, high shock loads, abrasive dust and high humidity etc will easily cause failure of equipment, unexpected downtime and difficulty for maintenance. Meanwhile, the global drastic competition is on the rise which make the bearings with high-precision and reliable performance essential. They need to increase the production capacity, reduce the cost and gain higher sustainability with the favor of a qualified bearing supplier. It’s a big challenge for bearing manufacturers.

ZWA is devoted to improving the quality of bearings for steel or metal mills continuously. With the great efforts, ZWA is able to help the customers realize the following goals by offering high quality ball bearings and roller bearings :

Increase the production capacity

Reduce the cost

Optimize the machine’s performance

Protect the environment

Reduce the frequency of maintenance

ZWA’s bearings for steel or metal mainly cover the range from continuous conticaster to hot & cold rolling mills and galvanizing mills.

For continuous conticaster, ZWA’s circular ring roller bearings and spherical roller bearings work together to meet the high temperature working condition. ZWA has become a professional China bearing supplier of many world famous steel companies home and abroad.

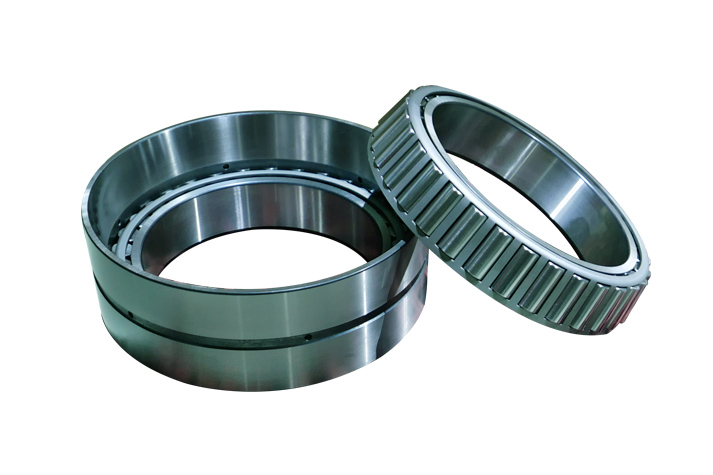

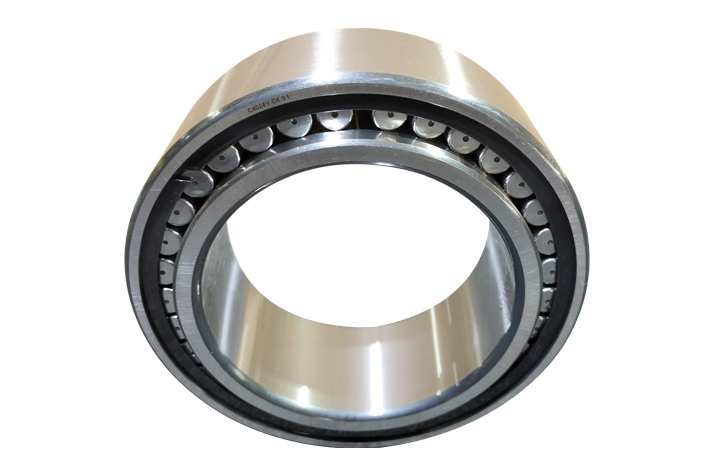

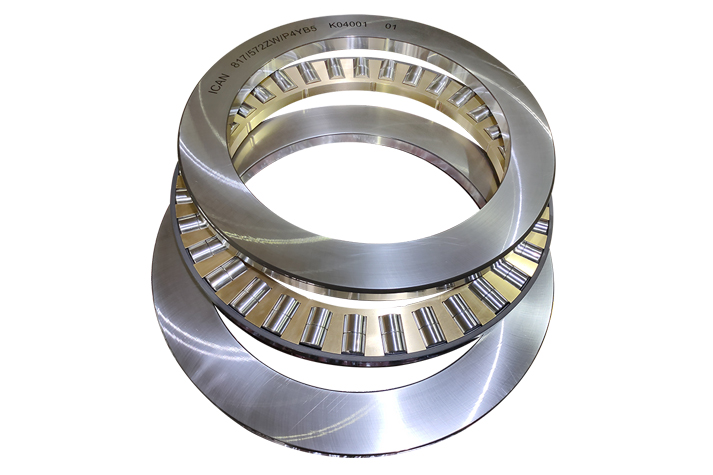

Mill stands in rolling mills includes several components and systems. All of them have to face high temperatures, high loads and other harsh working conditions. For hot and cold rolling mills, ZWA provide effective support for work-rolls, back-up rolls, galvanized rolls to ensure safe and efficient performance of the whole rolling mills. The bearings applied in rolling mills mainly consist of 2-row cylindrical and tapered roller bearings, 4-row cylindrical and tapered roller bearings, deep groove ball bearings, angular contact ball bearings and thrust bearings. Despite the regular and designated types, ZWA also the capability of offering newly-designing or optimizing the original bearing design based on the actual working condition.

| TYPE | Dimension (d*D*B) | Weight(KG) |

| 313445 | 330*460*340 | 175 |

| 313822 | 280*390*220 | 82.5 |

| 313824 | 230*330*206 | 58 |

| 313893 | 200*280*200 | 39 |

| 313921 | 240*330*220 | 58 |

| 24024CCW33C4 | 120*180*60 | 5.45 |

| 24026CCW33C4 | 130*200*69 | 8.05 |

| 24028CCW33C4 | 140*210*69 | 8.55 |

| 24030CC/C4W33 | 150*225*75 | 10.5 |

| 24032CCW33C4 | 160*240*80 | 13 |

| 24122CC/C4W33 | 110*180*69 | 7.1 |

| 395KV5401 | 395*545*288.7 | 196 |

| 67885XDW-810-820D/P5 | 207*266.7*188.912 | 32.7 |

| 67986DW-67920-67921D | 206.375*282.575*190.5 | 34.4 |

| BT4-8160 E8/C475 (6-77968ХМ) | 343.052*457.098*254 | 111 |

| C4024V | 120*180*60 | 5.5 |

| C4026V | 130*200*69 | 8.05 |

| C4028V | 140*210*69 | 8.55 |

| C4030V | 150*225*75 | 10.5 |

| C4032V | 160*240*80 | 12.6 |

| FCDP76108300/HCP54 | 380*540*300 | 220 |

| HM237545/HM237510CD/HCC9 | 177.8*288.925*142.875 | 32.44 |

| HM256849/HM256810CD/HTCS | 300.037*422.275*174.625 | 72.48 |

| HM259049/HM259010/HTCS | 317.5*447.675*85.275 | 41.94 |

| LM 272249DGW/210-210D | 482.6*615.95*330.2 | 235 |

| LM451349DGW/LM451310/LM451310CD | 266.7*355.6*228.6 | 64 |

| LM451349DW/LM451310/LM451310CD | 266.7*355.6*228.6 | 64 |

| LM761649DGW/10/10D/HCP59 | 343.052*457.098*254 | 111 |

| M 249730T/747TD/749T/710 | 234.422*358.775*292.1 | 95.1 |

| M244249/M244210CD/HTCS | 220.662*314.325*131.762 | 29.97 |

| M249748DW/M249710/M249710D | 254*358.775*269.875 | 85.6 |

| M252349DW-M252310-M252310CD | 269.875*381*282.575 | 110 |

| M278749DW/M278710/HTC9 | 517.5*812.8*285.75 | 500 |

| M281049DGW/M281010/M281010CD | 635*901.7*654 | 1387 |

| NP090602-9AK2 PSL612-348 | 500*720*418.5 | 568 |

| NP222798/NP224992/NP226599/HT | 480*700*418.5 | 568 |

| NP246425-90KA1(381176) | 380*620*418.5 | 515 |

| NP747477/NP892981/HTP6 | 450*680*180 | 263 |

| NP809306-NP809307 | 300*440*105 | 56 |

| NP815821-90KA1(381084) | 420*620*354.5 | 373.5 |

| NP827555 | 530*880*542 | 1344 |