Like steel and metal mills, mining is another industry whose working condition is extremely harsh. From thousands of meters high mountain to under earth, from extremely cold to extremely hot areas, you can see mining operating widely. Exposure to dust and dirt, higher vibration level, shock loads can easily cause the bearing overload, abrasion, contamination and lack of lubrication. In the end, unavoidable failure, costly shut-downs and loss of productivity will occur. Meanwhile, severe bad weather and abrasive contaminants also do harm both to the machine and the workers. In this case, mounting and dismounting of the bearings will take even greater efforts and face more difficulties. Therefore, mining industry set up extra strict requirements for the bearing service life and good performance. A reliable bearing supplier who is able to offer bearings with high-quality and longer service life is crucial and essential for mining customers.

The process of mining and mineral processing involves many operating challenges.In the past decades, ZWA contributed to R&D of bearings for mining and mineral processing based on its designing, analyse technology and raw material advantages. As a renowned manufacturer of different types of ball and roller bearings, ZWA has become the bearing suppliers of many pioneers in mining industry, including Metso, Astec Industries etc by helping them to realize the following goals:

Reduce the cost

Decrease the vibrating levels

Reduce the noise level

Fight for the contaminants

Increase the productivity

ZWA’s bearings for mining covers the range from sand maker, vibrating screen to crushers etc.

For sand maker, ZWA developed her own single-row cylindrical roller bearings which have been approved by numerous end users.

For vibrating screen, ZWA designed her own MBA cage for spherical roller bearings to compete with other brands. Meanwhile, ZWA also produced the bearings with CCJA, MA cage according to the customers’ requirements.

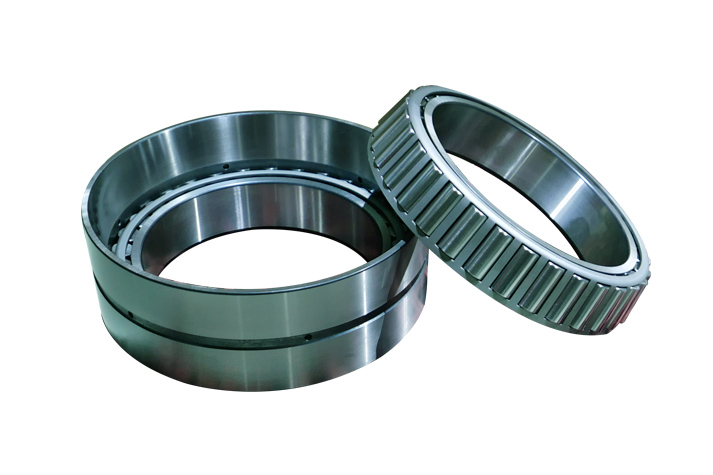

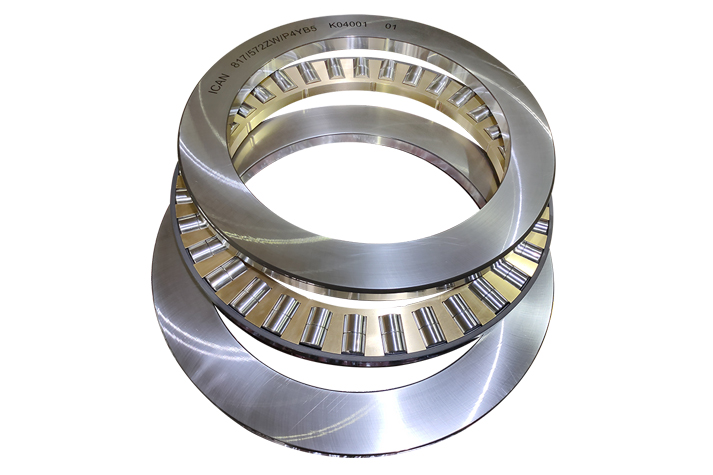

For crushers, ZWA is capable of offering all types of bearing, including spherical roller bearings, cylindrical thrust roller bearings, tapered roller bearings and ball bearings.

| TYPE | Dimension (d*D*B) | Weight |

| 22319CCJA/W33VA405 | 95*200*67 | 10.5 |

| 22320CCJA/W33VA405 | 100*215*73 | 13.5 |

| 22322CCJA/W33VA405 | 110*240*80 | 18.4 |

| 22324CCJA/W33VA405 | 120*260*86 | 23 |

| 22326CCJA/W33VA405 | 130*280*93 | 29 |

| 22328CCJA/W33VA405 | 140*300*102 | 36.5 |

| 22330CCJA/W33VA405 | 150*320*108 | 43.5 |

| 22332CCJA/W33VA405 | 160*340*114 | 52 |

| 22334CCJAW33VA405 | 170*360*120 | 61 |

| 22348CCJAW33VA405 | 240*500*155 | 155 |

| 22319MBAW33C4 | 95*200*67 | 10.5 |

| 22320MB/W33C4 | 100*215*73 | 13.5 |

| 22322MBW33C4 | 110*240*80 | 18.4 |

| 22324MBW33C4 | 120*260*86 | 23 |

| 22326MBW33C4 | 130*280*93 | 29 |

| 22328MBW33C4 | 140*300*102 | 36.5 |

| 22330MBW33C4 | 150*320*108 | 43.5 |

| 22332MBW33C4 | 160*340*114 | 52 |

| 22334MBW33C4 | 170*360*120 | 61 |

| 22336MBW33C4 | 180*380*126 | 71.5 |

| 22338MBW33C4 | 190*400*132 | 82.5 |

| 22340MBW33C4 | 200*420*138 | 95 |

| 23148CA/C3W33 | 240*400*128 | 66.5 |

| 22244CA/C3W33 | 220*400*108 | 60.5 |

| 22240CA/C3W33 | 200*360*98 | 43.5 |

| 23038CA/C3W33 | 190*290*75 | 18 |

| 23056CAC3/W33 | 280*420*106 | 52.5 |

| 23228CA/C4W33 | 140*250*88 | 19 |

| 23226CA/C4W33 | 130*230*80 | 14.5 |

| 23020CA/C4W33 | 100*150*37 | 2.51 |

| 23022CA/C4W33 | 110*170*45 | 3.8 |

| 22340CA/C4W33 | 200*420*138 | 95 |

| 22240CA/C3W33 | 200*360*98 | 43.5 |

| 22238CA/C3W33 | 190*340*92 | 36.5 |

| 22244CA/C3W33 | 220*400*108 | 60.5 |