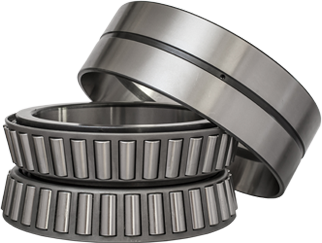

Single row tapered roller bearings as the most widely used tapered roller bearings consist of one outer ring, and one inner ring unit. The inner ring unit includes one inner ring, one group of tapered rollers and a cage. In ZWA’s same type single row tapered roller bearings,both inner ring and outer ring can be exchangeable with other inner rings and outer rings. In general, the tapered angle of outer ring raceway is between 10°~19° and the contact of roller and raceways is linear one . Therefore, it can bear combined axial and radial loads, also single axial loads. The bigger the tapered angle, the bigger axial load capacity can be accommodated. As the extending line of raceways meet at the same point of the bearing axis, in operation, single row tapered roller bearing has lower friction torque.

ZWA, as a China tapered roller bearing factory, offers pure single row tapered roller bearings and matched single row tapered roller bearings (i.e. back to back or face-to-face mode). According to different contact angles, single roller tapered roller bearings can be classified into three types: small cone angle, medium cone angle, and big cone angle. In the past years, ZWA has offered hundreds of pieces of single-row tapered roller bearings to customers. Those bearings help the customers reduce operational cost, increase productivity, sustain the equipment, and prolong the service life.

Features of Single Row Tapered Roller Bearings

Separable, both the inner ring and outer rings own tapered raceways. It’s easier and faster to realize assembling, disassembling, inspection, and maintenance.

Lower friction, the optimized roller design, and smooth ribs form a layer of lubrication film which reduces friction.

Lower noise level, the lower friction leads to the lower noise level.

Improve the reliability of the operation

Exchangeable, the separable parts are exchangeable

Tooling machine, reducer, automobile, agriculture, mining, steel & metal process, plastic machine etc.