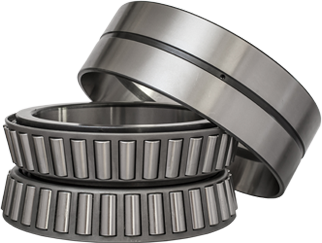

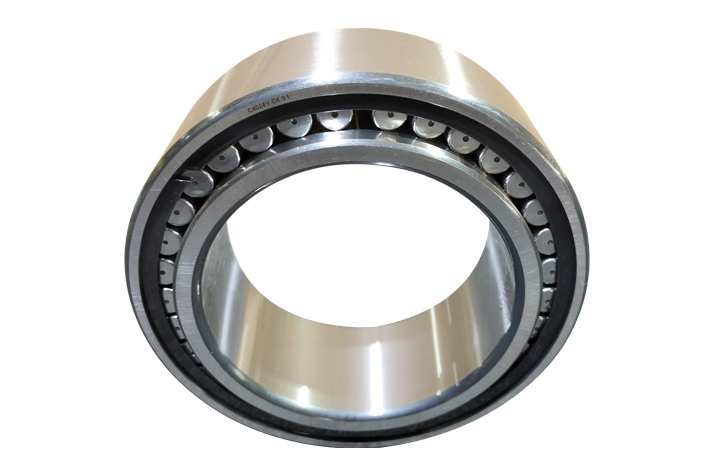

Toroidal roller bearings are kind of new single-row radial bearing. It has crowned symmetrical rollers and circular ring raceways.The rollers of the toroidal bearings are self-guiding, that’s to say they adjust the position in which the loads are averagely distributed over the length of the rollers no matter the inner ring is axial displaced or not. The raceways of the inner rings and outer rings are concave and arranged symmetrically about the center of the bearings. It combined the self-aligning features of spherical roller bearings and the unlimited axial replacement features of cylindrical roller bearings. Meanwhile, it has very small cross-sectional area which are the features of needle bearings. Toroidal bearings allows axial replacement if not causing extra axial loads or friction. But it is not positioning bearing and can only bear radial loads. ZWA’s toroidal roller bearings include the one with or without cages depending on the different requirements of the customers.

As toroidal roller bearing is difficult to produce. ZWA as one of the qualified producer, has offered thousands of pieces toroidal roller bearings to the customers, especially those continuous casters from steel industry. Those bearings must work until the rolls are abandoned after the fixed time. Therefore, the requirements for the bearings are extremely high and strict. ZWA’s customers for toroidal roller bearings cover from home and abroad. With ZWA’s toroidal roller bearings, the customers have realized the goal of reducing the cost, increasing the productivity, prolong the sustainability, reduce the space&weight, and maintain the equipment well.

Internal compact design

Permission for misalignment

Permission for radial displacement

Lower friction

Higher abrasion

Lower noise

The application of toroidal roller bearings covers a wide range for conditions of higher radial loads, like paper mills, continuous caster, stone crusher, transmission belt, grinding machine, textile machine and so on.