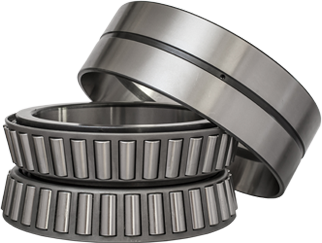

The rollers of two-row cylindrical roller bearings are crossing arranged. While rotating, the wave ratio is one time higher than single-row cylindrical roller bearings. However, the vibration ratio decreases 70%. And due to its two-row roller arrangement, compared with single-row cylindrical roller bearings, they are able to bear extremely higher load capacity.

Based on the different bore types, ZWA’s double-row cylindrical roller bearings are divided into two types, one is with cylindrical bore and the other is with a tapered bore. Based on a different arrangement of flanges on the inner ring and outer ring, and also the cage design, ZWA’s double-row cylindrical roller bearings are divided into NNU, NN, and NNUP types. For the NNU type, there are ribs on both sides of the outer ring but no ribs on the inner ring. For NN type, there are ribs on both sides of the inner ring but no ribs on the outer ring. For the NNUP type, there are ribs on both sides of the outer ring and ribs on one inner ring. While mounting the NNUP types, do make the marked ribs outward. In general, NU and NN types are used on the free end and NUP types on the fixed end.

ZWA offers double row cylindrical roller bearings both with machined brass and steel cages. With continuous efforts in improving the quality, as one of the leading China cylindrical roller bearing manufacturers and a double row cylindrical roller bearing factory, ZWA has helped customers realize the following goals by providing two-row cylindrical roller bearings:

Reduce the cost

Increase productivity

Prolong the equipment service life

Improve the sustainability

The features of two-row cylindrical roller bearings are as follows

Compact internal structure

Higher stiffness

Higher load capacity ability

Small deformation after high load

Lower friction

Longer service life

Improve the operational reliability

Separable and interchangeable

High-speed ability

The applications of two-row cylindrical roller bearings are as follows:

The spindle of tooling machine, rolling mills, gearboxes, grinding machines and so on.