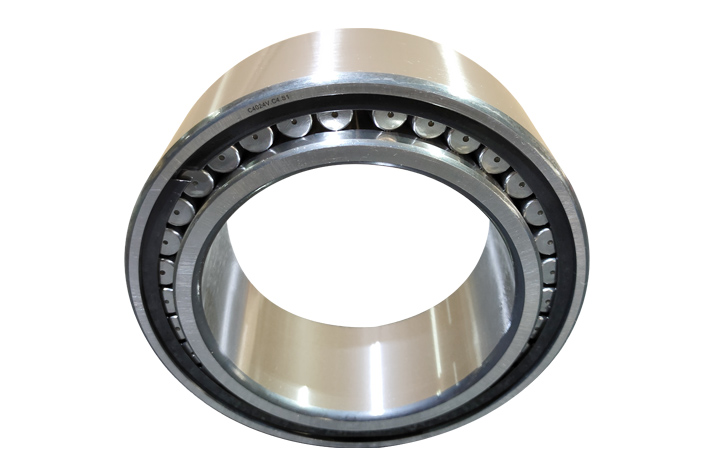

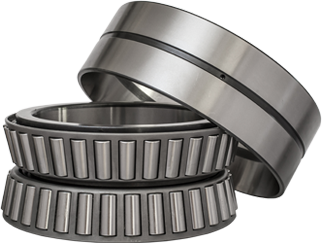

Split spherical roller bearings are specially designed based on the original spherical roller bearing and cylindrical bearing. The aim of split bearings is to solve the problem of quick replacement of bearings at unattainable positions or points. They are suitable for the application of lower rotating speed, higher load, shock loads, harsh working conditions and those positions where it is hard to access. ZWA’s split bearings include split spherical and split cylindrical roller bearings. The cages of split roller bearings are defaulted as brass ones. Meanwhile, ZWA bearings also offer complete split bearing units, including split roller bearing, housing, bracket and some joining elements. In this unit, in order for assembling and disassembling, the split roller bearing, housing, and bracket are all 180 degrees split on the axial direction.

In the past years, ZWA, as a leading China Split Bearing manufacturer, has offered hundreds of pieces of split spherical and cylindrical roller bearings to customers. With those bearings, ZWA helps customers to improve efficiency, reduce the downtime of the machine, decrease costs, increase productivity, and make assembling and disassembling easier and faster. As one of the rare qualified split bearing manufacturers, ZWA has a patent for its own split design which optimizes the way of split and also improves the precision of bearings. For the spherical split bearings, ZWA’s production range is from the inner ring 100mm to 406mm. And for the cylindrical split bearings, ZWA offers a customized design.

Separable and easy to assemble and disassemble

Accommodate the misalignment created initially

Reduce edge stress by rolling element

Longer service life

Split spherical roller bearings are mainly applied on the shafts which are supported by several unreachable points or positions, including transmission, material processing, ventilation equipment, mills, continuous casting, vessels, and paper making industry.

Examples of mining and material processes: cement, pulley, grinding and crusher, fan and ventilator, elevator, crane, transmission apparatus, and shaft.