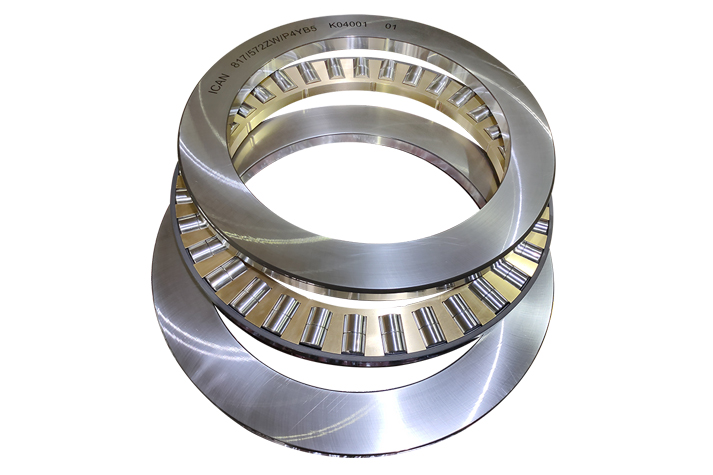

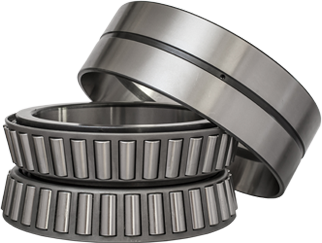

Four-row cylindrical roller bearings are kind of separable bearings. The rings and roller components are easily separable. With this feature, the washing, inspection, assembling, disassembling and maintenance are convenient and fast.

Based on the different bore types, ZWA’s four-row cylindrical roller bearings are divided into two types, one is with cylindrical bore and the other is with a tapered bore. Based on the different inner design, ZWA’s four-row cylindrical roller bearings are divided into FC, FCD, and FCDP types. FC type contains two outer rings, one inner ring, two flanges on outer rings, one center flange in the middle, and no flanges on the inner ring. The inner ring is a complete one. FCD type contains two NN type bearings. In common, FC and FCD type bearings adopt pressed steel cage. Type FCDP contains two inner rings and one loose rib on the outer ring. In general FCDP type’s cage is pin-type. Both FC and FCD type can bear axial displacement in two directions and bearings can usually apply in the free end. But as four-row cylindrical roller bearings mainly bear radial loads, in order to accommodate the axial loads, they usually match with deep groove ball bearings or angular contact ball bearings, or tapered roller bearings no matter radial one or thrust one.

ZWA Bearings offered four-row cylindrical roller bearings with both pressed steel cage and machined brass cage. ZWA’s four-row cylindrical roller bearings have mainly served the customers from steel or metal process. They helped the customer reduce the cost, increase productivity, and prolong the service life of the rolling mills.

Features of four-row cylindrical roller bearings

Higher radial load capacity

Lower friction

Compact internal structure

Higher stiffness

Higher precision

High rotating speed

Interchangeable

Application of four-row tapered roller bearings

The most popular and widely application is the steel &metal process including hot strip and cold strip rolling mills.