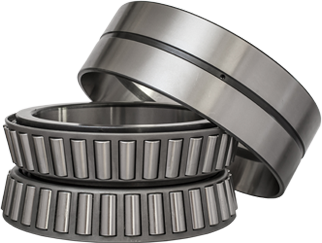

Double-row spherical roller bearings are the most widely used types in group of radial roller bearings. They have two rows of rollers, curved raceway in the outer ring and two raceways in the inner ring. The design of raceways make the bearings combine different characteristics in one bearing, for example, adjusting the angular loads. In general, the symmetrical rollers are guided by press steel cages or machined brass cages in ZWA’s production range.

The contact surface of the rollers will determine the allocation of stress at the contact points between the raceways and rollers. Owing to this feature, the geometry of rollers matches with the raceway.

In general, ZWA Bearing offers the two-row spherical roller bearings with both steel cage and brass cage, for the steel cage, it mainly contains CC type which has the following features:

Two pressed window-type steel cage, the inner ring is without flanges and a guide ring is centered on the inner ring.

For the brass cage, it mainly contains CA, MB, and MA types.

For CA cage, it has the following features

One machined brass cage, the inner ring is with retaining flange on both sides and one guide ring centered on the inner ring. The flange will keep the rollers in position while rotating the bearing in process of mounting or maintenance. It doesn’t guide the rollers or bear any axial load.

For MB cage, it has the following features

Two brass cages, inner ring guided with two retaining ribs and one central rib.

For MA cage, one brass cage, outer ring guided with two retaining ribs and one central rib.

ZWA’s double-row spherical roller bearings favor the customers to realize the following aims

Reduce the cost

Increase productivity

Higher machine availability

Features of double-row spherical roller bearings:

Bear high or very high radial loads

Bear relative high axial loads on one or both sides.

Reduce the friction

Compensate the misalignment

Application of double-row spherical roller bearings

Mining

Steel or metal process

Cement

Papermaking

Transmission