When it comes to heavy-duty applications and demanding industrial machinery, ensuring optimal performance and reliability is of utmost importance. One crucial component that plays a significant role in achieving these goals is the 4 row taper roller bearing. With its unique design and capabilities, this type of bearing offers unrivaled strength and performance, making it the ideal choice for various industries.

What sets the 4 row taper roller bearing apart from its counterparts is its ability to handle heavy loads and withstand high-speed operations. This bearing design incorporates four rows of rollers arranged in a tapered configuration, allowing for increased load-carrying capacity and enhanced thrust capability. This means that even under the heaviest loads and harshest operating conditions, the 4 row taper roller bearing can deliver optimal performance with minimal wear and tear.

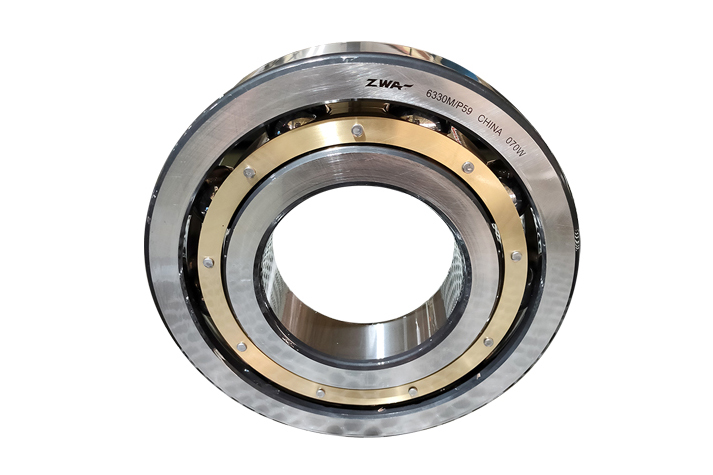

Advantages of the 4 Row Tapered Roller Bearing

One of the key advantages of the 4 row taper roller bearing is its ability to distribute load more evenly compared to other bearing types. With four rows of rollers, the load is spread across a larger contact area, reducing stress and minimizing the risk of premature failure or damage. This even distribution of load not only extends the bearing's lifespan but also improves the overall performance of the machinery it is installed in.

In applications where precision and smooth operation are crucial, the 4 row taper roller bearing excels. Its tapered design allows for precise adjustment of axial clearance, ensuring optimal contact between the rollers and the raceways. This precision adjustment not only reduces friction and heat generation but also minimizes vibrations and noise, resulting in smoother and quieter operation.

Additionally, the 4 row taper roller bearing offers excellent rigidity and stability, making it suitable for applications requiring high levels of accuracy and control. Its robust construction and advanced load-carrying capabilities allow it to handle heavy radial and axial loads without compromising performance. This makes it an ideal choice for industries such as mining, construction, steel manufacturing, and wind energy, where heavy machinery and extreme loads are the norm.

In summary, the 4 row taper roller bearing is a game-changer in the world of industrial machinery. Its ability to handle heavy loads, distribute load evenly, provide precision adjustment, and offer excellent rigidity and stability sets it apart from other bearing types. Whether it's a mining excavator, a steel rolling mill, or a wind turbine, the 4 row taper roller bearing proves its worth time and time again.

To ensure optimal performance and longevity, it is essential to choose a trusted brand when it comes to 4 row taper roller bearings. Look for a manufacturer that specializes in high-quality bearings, known for their durability and reliability in demanding environments. With the right bearing choice, you can quadruple the strength of your machinery and maximize its performance, allowing your business to thrive in even the most challenging conditions.

In conclusion, if you're seeking the utmost strength and performance in heavy-duty applications, the 4 row taper roller bearing is the answer. Its unique design, load-carrying capabilities, precision adjustment, and reliability make it the preferred choice for industries worldwide. Don't compromise on the foundation of your machinery – choose the power and durability of 4 row taper roller bearings.