The parts that support the relative rotation of the shaft are called bearings. Usually, it's axis rotation. There are also shafts that do not rotate but the housing rotates, such as automotive hub bearings.The difference between the bearing capacity of different types of bearings is also different. What are the different types of bearings and what are the common ones? The detailed introduction is as follows:

1. Deep groove ball bearings

Deep groove ball bearings have the advantages of simple structure, convenient use and the largest production volume, so they have the most wide application. They mainly bear radial load, and can also bear a certain axial load. When the radial clearance of the bearing increases, they have the function of angular contact bearings and can bear large axial load.

2. Self-aligning ball bearings

The self-aligning ball bearing has two rows of rigid balls, the inner ring has two raceways, and the outer ring raceway is inner spherical shape, which has the performance of automatic self-aligning. It can automatically compensate the coaxiality error caused by the bending of the shaft and the deformation of the shell. It is suitable for the parts where the bearing hole cannot guarantee the strict coaxiality. The bearing mainly bears radial load, and while bearing radial load, it can also bear a small amount of axial load. The bearing is usually not used to bear pure axial load. If it bears pure axial load, only one row of the rigid balls bears the load.

3. Angular contact ball bearings

Angular contact ball bearings have high limit speed and can bear radial and axial loads as well as pure axial loads at the same time. The axial load capacity is determined by the contact angle and increases with the increase of the contact angle.

4. Cylindrical roller bearings

The roller of a cylindrical roller bearing is usually guided by two flanges of a bearing ring. The cage, roller and guide ring constitute a combined part, which can be separated from another bearing ring, and belongs to a separable bearing. This kind of bearing is easy to install and disassemble, especially when the inner and outer rings are required to fit with the shaft and the shell. Such bearings are generally only used to bear radial loads, and only single row bearings whose inner and outer rings have flanges can bear smaller steady axial loads or larger intermittent axial loads.

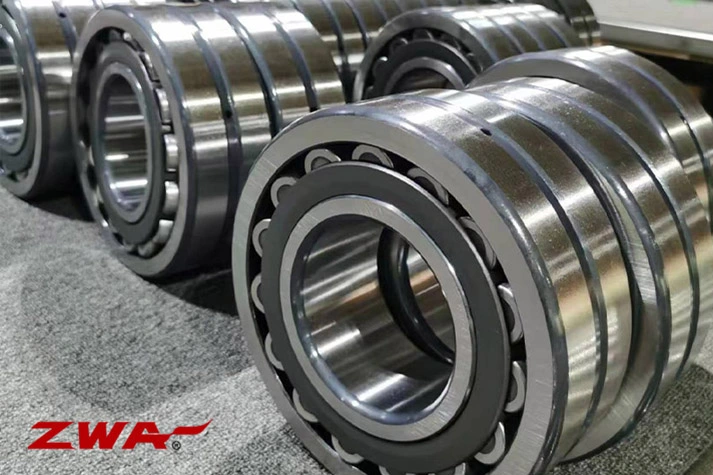

5. Self-aligning roller bearings

Self-aligning roller bearings have two rows of rollers, and are mainly used to bear radial load, but they can also bear axial load in any direction. This kind of bearing has high radial load capacity, so it is especially suitable for heavy load or vibration load work, but can not bear pure axial load; it has good self-aligning performance to compensate the bearing error.

6. Tapered roller bearings

Tapered roller bearings are mainly suitable for bearing radial load and axial combined load, and large cone angle tapered roller bearings can mainly be used to bear combined radial and axial load with axial load as the main load. This is a kind of separable bearing, and the inner ring (including tapered roller and cage) and the outer ring can be mounted separately. The radial clearance and axial clearance of the bearing can be adjusted in the process of installation and use, and interference installation can also be adopted.

7. Thrust ball bearings

Thrust ball bearing is a kind of separable bearing. The shaft ring and seat ring can be separated from the components of the cage and rigid ball. The shaft ring is a ring matched with the shaft, the seat ring is a ring matched with the bearing seat hole, and there is a gap between the shaft. Thrust ball bearings can only bear axial loads, one-way thrust ball bearings can only bear axial loads in one direction, and two-way thrust ball bearings can bear axial loads of two directions. Thrust ball bearings can not limit the longitudinal displacement of the shaft, and the limit speed is very low. One-way thrust ball bearings can limit the axial displacement of the shaft and housing in one direction, and two-way bearings can limit the axial displacement in two directions.

8. Thrust self-aligning roller bearings

Thrust self-aligning roller bearings are used to bear combined axial and radial loads with axial load as the main load, but the radial load shall not exceed 55% of the axial load. Compared with other thrust roller bearings, this kind of bearing has lower friction coefficient, higher speed and self-aligning ability. The 29000 type roller bearing is a kind of asymmetric spherical roller, which can reduce the relative sliding between the roller and raceway in operation. In addition, oil lubrication is usually adopted because the roller is long, the diameter is large, the number of rollers is large, and the load capacity is high. Grease lubrication can be used in individual low speed bearing. Such bearings should be given priority in design and selection.

9. Needle roller bearings

Needle roller bearings are equipped with thin and long rollers (the length of the roller is 3~10 times of the diameter, and the diameter is generally not greater than 5 mm), so the radial structure is compact. When the inside diameter size and load capacity are the same as other types of ball and roller bearings, needle roller bearings have the smallest outside diameter, which is especially suitable for supporting structures with limited radial installation size. According to different use occasions, the bearing without inner ring or needle rolling and cage assembly can be selected. At this time, the journal surface and shell hole surface matching with the bearing can be directly used as the inner and outer rolling surfaces of the bearing. In order to maintain the same load capacity and running performance as the bearings with rings, the surface hardness, machining accuracy and surface quality of the shaft or shell hole raceway shall be similar to those of the bearing ring raceway. This kind of bearing can bear only radial load.

10. Outer spherical ball bearing with seat

The outer spherical ball bearing with seat is composed of an outer spherical ball bearing with seal in two sides and a cast (or steel sheet stamped) bearing seat. The internal structure of the outer spherical ball bearing is the same as that of the deep groove ball bearing, but the inner ring of the bearing is wider than the outer ring, and the outer ring has a truncated spherical outer surface, which can automatically align with the concave sphere of the bearing seat. Generally, there is a gap between the inner hole of this bearing and the shaft. The inner ring of the bearing is fixed on the shaft with the jackscrew, eccentric sleeve or the set sleeve, and it rotates together with the shaft. Bearings with seats have compact structure, easy assembly and disassembling and perfect sealing, which are suitable for simple support and often used in mining, metallurgy, agriculture, chemical industry, textile, printing and dyeing, conveying machinery, etc.