In the realm of machinery manufacturing, the utilization of various types of rolling bearings is paramount to ensure smooth operation and longevity of equipment. Among these, two prominent types stand out: spherical roller bearings and cylindrical roller bearings. In this article, we delve into the key differences and applications of spherical roller bearings and cylindrical roller bearings, providing readers with valuable insights to guide their bearing selection process.

Spherical roller bearings are rolling bearings with inner and outer rings, which are characterized by a large bearing capacity, self-adjustment of angular deviation, and resistance to load shocks. Spherical roller bearings are able to withstand large radial loads and certain axial loads and rotational speeds.

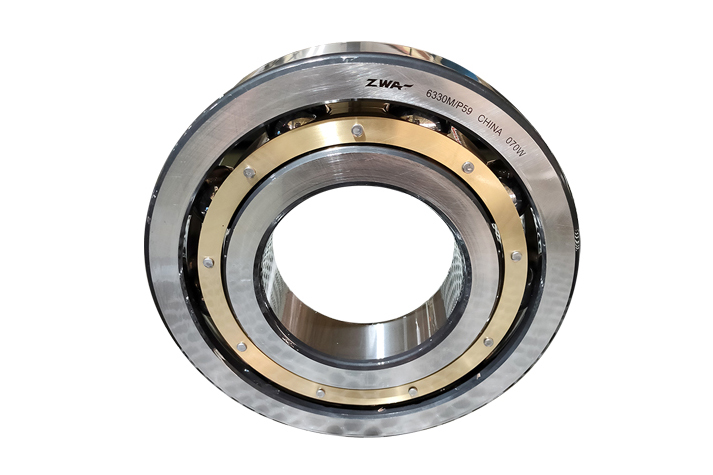

Cylindrical roller bearings are also a commonly used type of rolling bearings, which are characterized by a high bearing capacity and are suitable for bearing support under high speeds and large radial loads. Cylindrical roller bearings run relatively smoothly even when subjected to different loads.

Structural form is different: Spherical roller bearings can freely adjust the tilt angle of the bearing centerline to adapt to different load conditions. Cylindrical roller bearings structure for the inner and outer rings are directly combined.

Different bearing capacity: Spherical roller bearings are suitable for larger radial loads, certain axial loads and rotational speeds, as well as the need for the bearing inner and outer rings to have a certain angle of self-adjusting ability of the occasion. Cylindrical roller bearings are suitable for high-speed operation and larger radial loads under the bearing support.

The scope of application is different: Spherical roller bearings are suitable for need to withstand large angular deviation and axial load mechanical equipment, such as mining machinery, iron, and steel metallurgical equipment, heavy machinery, etc.; and cylindrical roller bearings are suitable for precision machining, high-speed operation and other high requirements of mechanical equipment.

Spherical roller bearings and cylindrical roller bearings are commonly used rolling bearings in machinery manufacturing. Through the introduction of this article, readers could understand the difference between spherical roller bearings and cylindrical roller bearings, which helps to choose the bearings suitable for their mechanical equipment.