The lubrication purpose of the rolling bearing is to reduce the internal friction and prevent it from burning and sticking. The lubrication effect is as follows:

The contact part of the bearing ring, rolling body and retainer can prevent metal contact and reduce friction and damage.

The rolling fatigue life of the bearing is prolonged in the rotation when the rolling contact surface is well lubricated. On the contrary, the fatigue life will shorten if the oil viscosity is low and the oil film thickness is not good.

The circulating oil method can be used to remove heat generated by friction or heat transmitted from the outside, as well as cooling down. It prevents bearings from overheating and lubricating oil from aging.

It is also necessary to prevent foreign matter from entering the inside of the bearing, or to prevent rust and corrosion.

Methods of bearing lubrication:

The lubrication method for bearings can be divided into grease lubrication and oil lubrication. In order to make the bearing function well, it is necessary to choose a suitable lubrication method for the use of conditions and purposes. If only take lubrication into the consideration, the lubricity of oil lubrication is dominant. However, grease lubrication has the advantage of simplifying the structure around the bearing.

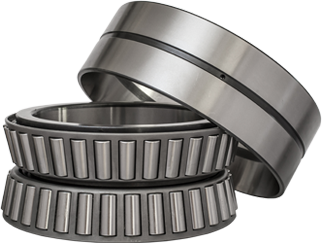

Click for all types of ball and roller bearings here!