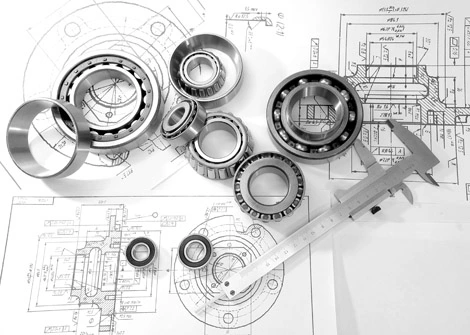

Which bearing can function as the high speed bearing?

The heating of bearings is related to the size of the adjacent surface and the relative speed of the adjacent surface (element). The creative idea of the multilayer bearing increases the heat dissipation surface and reduces the relative speed between the two surfaces. If the relative speed is too high to dissipate heat, it causes exfoliation for the surface and also damages the bearing. The biggest fear of cars and trains is the lock-up failure, which causes hot shaft, then hot saw, derailment, overturn and subversion, bringing great damage to people's life and property. In the past, people hoped that when the bearing of a wheel was locked (locking at one level), the inner or outer ring of the bearing would instantly slide against its contact surface. Even a little slithering could be a life-saving straw that can last one or two minutes for emergency braking and stopping. The most fearful thing is the overturn and subversion caused by locking up during an emergency stop. The introduction of multilayer adds "security" and "safety factor", increasing the chance of survival.

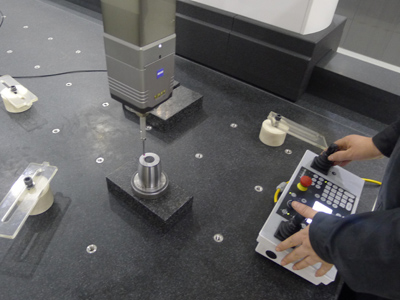

High speed bearing requires that after the rotary system of bearings undergoing precise dynamic balance, the parts of the shaft and seat hole shall have higher dimensional and shape accuracy than the general requirements, especially the concentricity and the perpendicular of the shoulder to the seat hole or journal. When considering these problems, we also must pay attention to the high speed bearing operation and high-temperature factors.

The shaft support system requires that it has high rigidity and it is as light as possible. In order to overcome this contradiction, measures such as reducing surface roughness and enhancing surface strength can be taken to improve the stiffness of support. Besides, it can be achieved by using hollow shafts to reduce system mass.