Cylindrical roller bearings are critical components in machinery and equipment, providing support and reducing friction between moving parts. With numerous types of cylindrical roller bearings available, selecting the right one for your application is essential. In this article, we will explore the different cylindrical roller bearing types and provide guidance on how to choose the most suitable option.

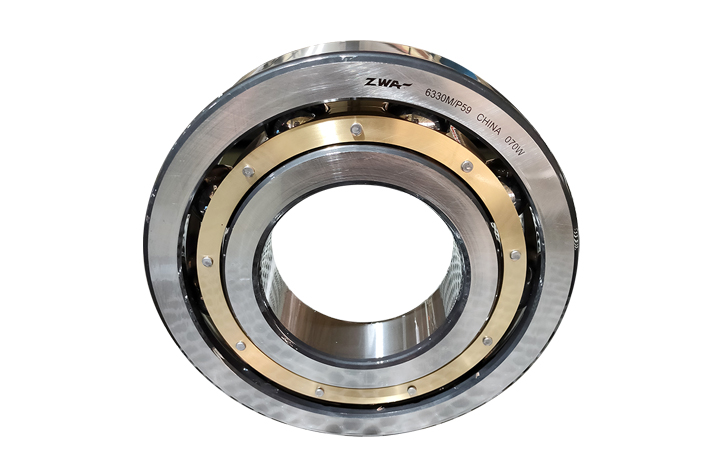

Before delving into the various cylindrical roller bearings types, it is important to have a basic understanding of how they work. China cylindrical roller bearings consist of cylindrical rollers arranged in parallel on a cylindrical inner and outer raceway. They are designed to handle heavy radial loads and are suitable for high-speed applications. The design also allows for easy installation and removal, making them versatile and widely used in different industries.

There are several types of cylindrical roller bearings, each with its own unique features and advantages. The most common types include:

Single Row Cylindrical Roller Bearings: As the name suggests, these bearings consist of a single row of cylindrical rollers. They can accommodate radial loads and moderate axial loads in one direction. Single row cylindrical roller bearings are ideal for applications with limited space and low to moderate speeds.

Double Row Cylindrical Roller Bearings: These bearings feature two rows of cylindrical rollers, providing increased load-carrying capacity compared to single-row bearings. They are suitable for heavy-duty applications that require high radial and axial loads, making them commonly used in mining, construction, and industrial machinery.

Full Complement Cylindrical Roller Bearings: In this type of bearing, the space between the rollers is filled, maximizing the load capacity. Full complement cylindrical roller bearings excel in applications with extremely heavy radial loads, such as in steel mills and heavy machinery.

Multi-Row Cylindrical Roller Bearings: Multi-row cylindrical roller bearings consist of multiple rows of cylindrical rollers, offering even higher load-carrying capacity. They are typically used in applications that require high rigidity and precision, such as machine tool spindles and printing presses.

Selecting the right cylindrical roller bearing type requires careful consideration of various factors, including:

Load Requirements: Determine the magnitude, direction, and frequency of the loads your bearing will encounter. This will help identify the appropriate load-carrying capacity required from the bearing.

Speed: Consider the rotational speed at which the bearing will operate. Higher speeds may require specific designs that can handle the increased heat and friction generated.

Space Constraints: Evaluate the available space for the bearing installation. Different types of cylindrical roller bearings have varying dimensions, and it is crucial to choose one that fits within your specific application's limitations.

Environmental Conditions: Take into account the operating environment, including temperature, humidity, and potential exposure to contaminants. Certain bearing types are designed to withstand extreme conditions better than others.

When in doubt, it is always beneficial to seek guidance from experts or ZWA. We can provide valuable insights into selecting the most suitable cylindrical roller bearing type for your application. By considering our expertise and utilizing our product knowledge, you can make an informed decision that optimizes the performance and longevity of your machinery.

In conclusion, selecting the right cylindrical roller bearing types is essential for the efficient and reliable operation of your machinery. By understanding the various types available, considering factors like load requirements, speed, space constraints, and consulting with experts, you can make an informed decision and ensure the longevity and performance of your application.