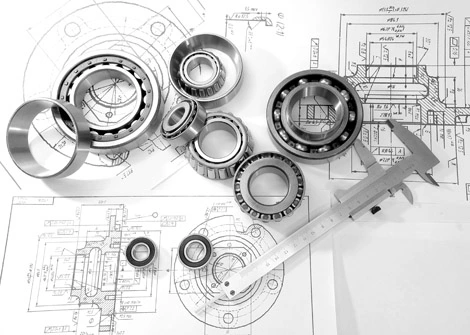

As a typical roller diameter bearing of rolling mills, the ring and the rolling component of four row cylindrical roller bearings can be easily separated from each other and interchanged in high precision. It is very convenient to install, disassemble and clean. Within a given radial installation space, it can provide the maximum radial bearing capacity and has a low inspection coefficient. China bearing manufacturer DALIAN GUANGYANG BEARING CO., LTD. will introduce the three structure types of four-row cylindrical roller bearings: FC, FCD and FCDP.

FC type four row cylindrical roller bearings belong to separable bearings, and they are mainly small bearings. The whole inner ring can be separated from the whole set of bearings. The whole set of bearings is composed of two outer ring components and one inner ring (consisting of one inner ring, two outer rings, four rows of rolling elements and two cages) with high limit speed and interchangeability. The cage is machined brass cage. Such bearings must first be suitable for high-speed (35m/s) rotation, while the bearing capacity takes a back seat. Generally, four row cylindrical roller bearings with inner warp of 80 mm~260 mm are designed for this structure to mainly be used for work roll parts of 4-row, 6-row and 12-row cold rolling mills.

FCD type four row cylindrical roller bearings belong to separable bearings, and they are mainly large bearings. The complete set of bearings consists of two outer ring assemblies and two inner rings (consisting of two inner rings, two outer rings, four rows of rolling elements and two cages) with high limit speed and interchangeability. The cages shall be machined brass or steel. This kind of bearing is not only suitable for high speed rotation (35m/s) but also can bear heavy load. Generally, four row cylindrical roller bearing with inner warp of 260 mm~400 mm is designed for this structure to be widely used in profile finishing mills and parts of high speed wire roughing rolling, medium rolling and pre-finishing rolling, including the back-up roll, middle roll and work roll parts of cold nonferrous and ferrous metal rolling mills below 950.

FCDP type four row cylindrical roller bearings are dominated by super-huge bearings, and the rolling mill roll diameter bearing is typical in this FCDP type. The parts can be easily separated from each other and interchanged in high precision. It is very convenient to install, disassemble and clean. Within a given radial installation space, it can provide the maximum radial bearing capacity and has a low inspection coefficient. Therefore, it is suitable for the mill roll diameter of high speed, heavy load and bad working environment.

In order to accommodate the maximum number of rolling elements to provide the best radial bearing capacity, the cage of four row cylindrical roller bearing with an inner warp of more than 400 mm is generally designed as a pin cage. The cage consists of two washers of a lateral limiting roller and a pillar connecting the two washers and passing through the center of the roller. That is, this kind of cage is composed of 2 inner rings, 2 outer rings, 4 rows of rollers, 1 middle check ring, 2 side check rings and 4 cages. Besides, the final pillar ends and washers are riveted by argon arc welding, so the cage has higher strength. This is very important for bearings that are subjected to frequent shocks or to great acceleration and deceleration (such as section slabs and high-speed reversible rolling mills).