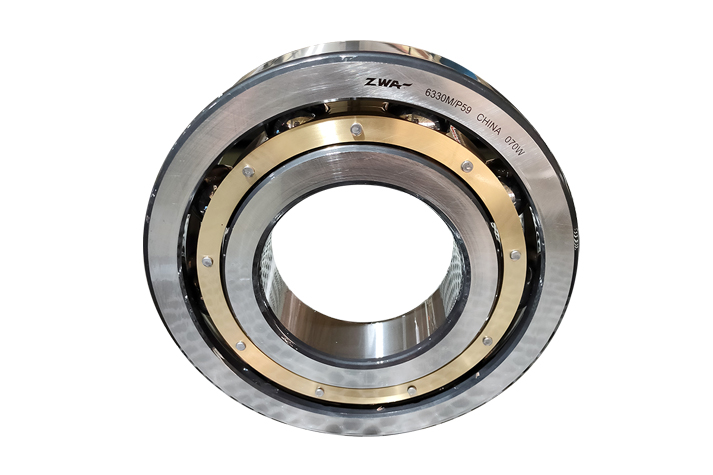

Angular contact ball bearing, also known as ACBB, is a kind of inseparable bearing. As an angular contact ball bearing manufacturer and supplier, ZWA produces bearings where the side shoulders of the inner ring and outer ring are uneven. In order to increase the load capacity, one of the side shoulders will be lower than the other. These bearings have raceways on both the inner ring and outer ring, allowing the inner ring and outer ring to make relative movement in the axial direction. Angular contact ball bearing applications are widely seen in many industries, as they can bear combined radial and axial loads and also work at higher rotating speeds. In general, the bigger the contact angle, the higher the axial load capacity is. ZWA’s angular contact ball bearings usually come with a brass cage and are available in various sizes and dimensions with different numbers, all manufactured by ZWA Bearings.

Load Handling:

Angular Contact Ball Bearings: Handle combined loads (radial + axial).

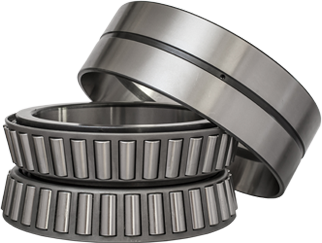

Thrust Bearings: Handle pure axial loads only.

Design:

Angular Contact Ball Bearings: Inner/outer rings with balls at a contact angle (15°-40°).

Thrust Bearings: Two washers with rolling elements (balls, rollers) perpendicular to the shaft.

Applications:

Angular Contact Ball Bearings: High-speed, high-precision applications (e.g., machine tools, pumps).

Thrust Bearings: Axial load applications (e.g., automotive clutches, crane hooks).

Performance:

Angular Contact Ball Bearings: High rigidity, accuracy, and speed capability.

Thrust Bearings: Optimized for axial loads, lower speed capability.

Mounting:

Angular Contact Ball Bearings: Often paired for bidirectional axial loads; precise alignment required.

Thrust Bearings: Mounted perpendicular to the shaft; simpler installation.