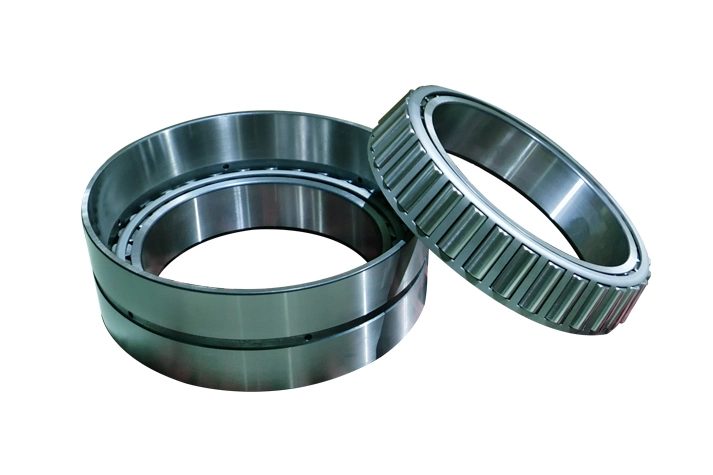

Tapered Roller Bearings

Tapered roller bearings, also known as TRB bearing, are also a kind of bearing that can be separated, a tapered raceway featured the inner and outer rings. Tapered roller bearings can bear large axial forces and function like thrust bearings. They can also manage large radial loads. Tapered bearings are an improvement on journal bearings. Tapered roller bearings don’t need to add frequent lubrication to avoid overheating and failure.

Tapered Roller Bearing Designation and Size Chart

Types of Tapered Roller Bearings

Many industries use tapered roller bearings, especially those in the steel and mining industries. Tapered bearings are essential to axle systems, rolls, engine motors, gear boxes, and reducers. They function best in medium-speed, heavy-load applications.

-

It can bear simultaneously radial load and single row axial load. According to contact angle, it is classified into 3 types: small, medial and big cone angle.Single Row Tapered Roller Bearing

It can bear simultaneously radial load and single row axial load. According to contact angle, it is classified into 3 types: small, medial and big cone angle.Single Row Tapered Roller Bearing -

It is classified into 2 types: capped and open. Both of them can bear radial and double row axial loads.Double Row Tapered Roller Bearing

It is classified into 2 types: capped and open. Both of them can bear radial and double row axial loads.Double Row Tapered Roller Bearing -

It is widely applied to low speed and medium speed rolling mills. The internal clearance is adjusted and makes it easier to operate.Four Row Tapered Roller Bearing

It is widely applied to low speed and medium speed rolling mills. The internal clearance is adjusted and makes it easier to operate.Four Row Tapered Roller Bearing -

This bearing can form a compact assembling in axial direction. The bearing is stiff and can bear heave axial loads but is insensitive to radial loads.Tapered Roller Thrust Bearing

This bearing can form a compact assembling in axial direction. The bearing is stiff and can bear heave axial loads but is insensitive to radial loads.Tapered Roller Thrust Bearing

Tapered Roller Bearings Features

1. High Load Capacity

2. Reduced Friction

3. High Rigidity

4. Long Service Life

5. Easy Installation and Maintenance

Consistency of roller profiles and sizes

The rollers incorporated in ZWA Bearings tapered roller bearings are manufactured to such close dimensional and geometrical tolerances that they are practically identical. This provides optimal load distribution, reduces noise and vibration, and enables preload to be set more accurately.

Rigid bearing application

A single row tapered roller bearing is typically adjusted against a second tapered roller bearing. By applying a preload, a rigid bearing application can be achieved.

Running-in period with reduced temperature peaks

Tapered roller bearings typically have a running-in period, during which a conventional design tapered roller bearing experiences a significant amount of friction, resulting in wear. This effect is noticed as a temperature spike. With ZWA tapered roller bearing designs, friction, frictional heat and wear are significantly reduced, provided the bearings are mounted and lubricated correctly.

ZWA is looking for distributors all over the world. If you are a quality-oriented distributor, if you suffer from long term delivery and after-sale service, if you want to increase the profit, contact us. ZWA bearings live up your expectations.