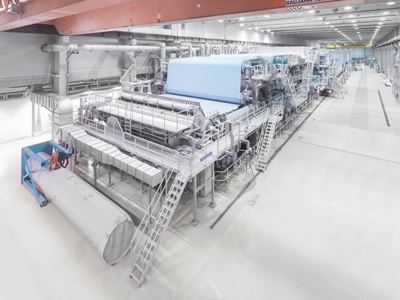

Different types of ball bearings and industrial roller bearings produced by ZWA Bearings can be applied in many sectors, including steel, mining, cement, paper making, and many other industries. ZWA, with strong roller and ball bearing business, is devoted to producing precision bearings for our customers' needs.